| |

|

|

| |

|

RTD

Sensors

|

Resistance Temperature

Detectors (RTDs) are one type of temperature

sensors. RTD changes the resistance with

respect to temperature. It measure temperature

because of the physical principle of the

positive temperature coefficient of electrical

resistance of metals. The hotter they become,

the larger or higher the value of their

electrical resistance.

The RTD element consists of a thin film

of platinum or nickel which is deposited

onto a ceramic substrate and laser trimmed

to the desired resistance. Thin-film elements

attain higher resistances with less metal

and, thus, tend to be less costly then the

equivalent wire-wound element. RTDs also

called resistance thermometer.

Resistance thermometers require a small

current to be passed through in order to

determine the resistance. This can cause

resistive heating, and manufacturers' limits

should always be followed along with heat

path considerations in design. Lead wire

resistance should be considered, and adopting

three and four wire connections can eliminate

connection lead resistance effects from

measurements. Industrial practice is almost

universally to use 3-wire connection. 4-wire

connection needs to be used for precise

application.

Some metals have a very predictable change

of resistance for a given change of temperature.

A precision resistor is made from one of

these metals to a nominal ohmic value at

a specified temperature. By measuring its

resistance at some unknown temperature and

comparing this value to the resistor's nominal

value, the change in resistance is determined.

Because the temperature vs. resistance characteristics

are also known, the change in temperature

from the point initially specified can be

calculated.

|

| |

Common

Resistance Materials for RTDs

|

• Platinum

(most popular and accurate)

• Nickel

• Copper

• Balco (rare)

• Tungsten (rare)

|

| |

What

are the parameters to select a right RTD

sensor?

|

• Sensor

material

• Temperature coefficient

• Nominal resistance

• Wiring configuration

|

| |

Temperature

Range

|

Platinum RTD's

can measure temperatures from -200°C

to 650°C. You must consider the temperature

limitations of all the materials involved,

where they are applied, and the temperatures

to which each will be exposed.

|

| |

Temperature

Coefficient

|

The temperature

coefficient (TC), or alpha of an RTD is

a physical and electrical property of the

metal alloy and the method by which the

element was fabricated. The alpha describes

the average resistance change per unit temperature

from the ice point to the boiling point

of water.

RTDs are manufactured from metals whose

resistance increases with temperature. Within

a limited temperature range, the resistivity

increases linearly with temperature. Each

metals specific, and unique resistivity,

can be determined experimentally. This resistance

is directly proportional to a metal wire's

length, and inversely proportional to the

cross-sectional area.

R = k L / A

where

R = resistance (ohm, O)

k = constant of proportionality or resistivity

of the material (ohm, O)

L = length of conductor (m)

A = cross sectional area of conductor (m2)

Resistivity and temperature can be expressed

as

kt = ko [1 + a (t - to)]

where

kt = resistivity at temperature t (ohm,

O)

ko = resistivity at standard temperature

to (ohm, O)

a = temperature coefficient of resistance

(1/oC)

t = temperature (oC)

to = standard temperature (oC)

|

Resistance

thermometer elements

|

Resistance thermometer

elements are available in a number of forms.

The most common are:

• Wire wound in a ceramic insulator

- wire spiral within sealed ceramic cylinder,

works with temperatures to 850 °C

• Wire encapsulated in glass - wire

around glass core with glass fused homogenously

around, resists vibration, more protection

to the detecting wire but smaller usable range

• Thin film - platinum film on ceramic

substrate, small and inexpensive to mass produce,

fast response to temperature change

|

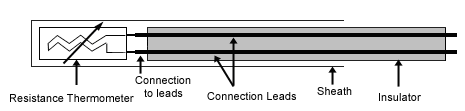

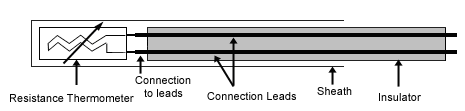

| |

Resistance

thermometer construction

|

|

These elements

nearly always require insulated leads attached.

At low temperatures PVC, silicon rubber

or PTFE insulators are common to 250°C.

Above this, glass fiber or ceramic are used.

The measuring point and usually most of

the leads require a housing or protection

sleeve. This is often a metal alloy which

is inert to a particular process. Often

more consideration goes in to selecting

and designing protection sheaths than sensors

as this is the layer that must withstand

chemical or physical attack and offer convenient

process attachment points.

|

| |

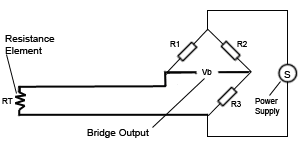

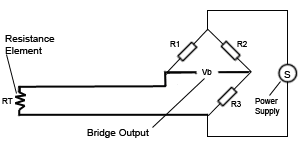

Resistance

thermometer wiring configurations

|

Two-wire

configuration

The simplest resistance thermometer configuration

uses two wires. It is only used when high

accuracy is not required as the resistance

of the connecting wires is always included

with that of the sensor leading to errors

in the signal. Using this configuration

you will be able to use 100 meters of cable.

This applies equally to balanced bridge

and fixed bridge system.

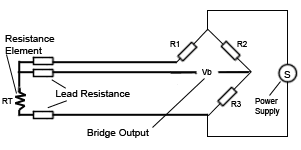

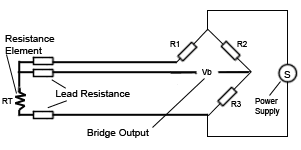

Three-wire configuration

In order to minimize the effects of the

lead resistances a three wire configuration

can be used. Using this method the two leads

to the sensor are on adjoining arms, there

is a lead resistance in each arm of the

bridge and therefore the lead resistance

is cancelled out. High quality connection

cables should be used for this type of configuration

because an assumption is made that the two

lead resistances are the same. This configuration

allows for up to 600 meters of cable.

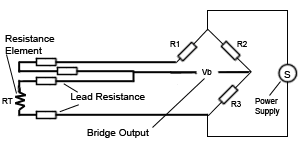

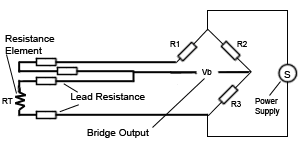

Four-wire configuration

The four wire resistance thermometer configuration

even further increases the accuracy and

reliability of the resistance being measured.

In the diagram above a standard two terminal

RTD is used with another pair of wires to

form an additional loop that cancels out

the lead resistance. The above Wheatstone

bridge method uses a little more copper

wire and is not a perfect solution. Below

is a better alternative configuration four-wire

Kelvin connection that should be used in

all RTDs. It provides full cancellation

of spurious effects and cable resistance

of up to 15 O can be handled. Actually in

four wire measurement the resistance error

due to lead wire resistance is zero.

|

SPECIFICATION

|

Range: -220

to 850°C for platinum RTDs and -200

to 340°C for Nickel RTDs

Linearity: Platinum and copper are more

linear. Nickel and Balco are less.

Sensitivity: -10 to 100 ohms/degree

|

| |

Advantages

|

• High accuracy

• Low drift

• Wide operating range

• Suitability for precision applications

• Stable output for long period of time

• Ease of recalibration

• Repeatability

• Not affected by the corrosion or oxidation

|

| |

Limitations

|

• RTDs

in industrial applications are rarely used

above 660 °C. At temperatures above

660 °C it becomes increasingly difficult

to prevent the platinum from becoming contaminated

by impurities from the metal sheath of the

thermometer. So that laboratory standard

thermometers replace the metal sheath with

a glass construction. At very low temperatures,

say below -270 °C (or 3 K), there are

very few phonons, the resistance of an RTD

is mainly determined by impurities and boundary

scattering and thus basically independent

of temperature. As a result, the sensitivity

of the RTD is essentially zero and therefore

not useful.

• Compared to thermistors, platinum

RTDs are less sensitive to small temperature

changes and have a slower response time.

However, thermistors have a smaller temperature

range and stability.

|

| |