| |

|

|

| |

Load

Cells

|

Working

|

Load cells works

like calibrated spring. It used for measuring

forces or for weighing system. It converts

force or weight into electrical signal.

A load cell usually consists of four strain

gauges in a Wheatstone bridge configuration.

Load cells of one or two strain gauges are

also available. The gages are developed

from an ultra-thin heat-treated metallic

coil and are chemically bonded to a thin

dielectric layer. "Gage patches" are then

mounted to the strain element with specially

formulated adhesives. The precise positioning

of the gage, the mounting procedure, and

the materials used all have a measurable

effect on overall performance of the load

cell. Wheatstone bridge with strain gauges

that measure this mechanical flexion hence

giving a proportional electrical signal.

This electrical signal is amplified by instrumentation

amplifier because electrical signal output

is very low. Load cells are used for sensing

large, static or slowly varying forces with

little deflection.

|

| |

Load cell

types

|

| • Double

ended shear beam

• Single ended shear beam

• Single column

• Multi column

• Membrane

• Torsion ring

• Bending ring

• Pancake

• Digital Electromotive Force

|

| |

Strain

gauge load cell

|

Strain gauge

load cell consist of a structure that elastically

deformed when subjected to a force and Strain

gauge network produces an electrical signal

proportion to deformation. Example of this

type of load cells are: Beam type load cell,

Ring type load cell.

|

Beam type load cell |

Beam type load cell are commonly employed for low level loads. Four strain gauge, two on the top surface and two on the bottom surface is used as elastic member for a load cell. The range and sensitivity of this beam type load cells depends upon the shape of the cross section, location of point of application of the load and fatigue strength of the material from which beam type load cell is fabricated. |

Ring type load cell |

Ring type load cell has a ring as elastic material. The ring element can be designed to cover a very wide range of loads by varying diameter D, thickness T or the depth of the ring. The load P is directly proportional to the output voltage Eo. The range of ring type load cell controlled by the strength of material used in fabricating the ring. |

|

Styles

of load cells |

| |

Compression/Tension Load

Cells

Compression/tension load cells can be used

for applications where the load may go from

tension to compression and vice versa. They

are ideal for space restricted environments.

|

S-Beam Load Cells

S-Beam load cells get their name from their

S shape. S-Beam load cells can provide an

output in under tension or compression.

Applications include tank level, hoppers

and truck scales.

|

Bending Beam Load Cells

Used in multiple load cell applications,

tank weighing and industrial process control.

Used in multiple load cell applications,

tank weighing and industrial process control.

|

Platform and Single Point

Load Cells

Platform and single point load cells are

used to commercial and industrial weighing

systems. They provide accurate readings

regardless of the position of the load on

the platform.

|

| |

What are

the factors to select a load cell?

|

• Capacity (kgs, pounds)

• Basic type and mode of operation

• Performance or accuracy level -related

to system requirements.

• Method of mounting.

• Approval requirements (metrological,

safety, environmental)

• Material of construction.

• Cost.

|

| |

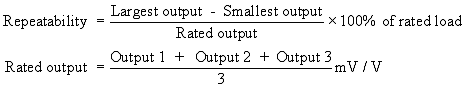

Repeatability

|

Repeatability is the agreement

between the results of successive measurements

of the load cell output for repeated applications

of a given force applied in the same direction.

Repeatability is normally measured by applying

the full rated load to the load cell three

times under carefully controlled conditions.

Environmental conditions must remain constant

during the test. The measurements are carried

out at the full rated load of the load cell

so the rated output is the average of the

three output values obtained from the test.

Output values can be expressed as millivolts

per volt (mV/V) or millivolts (mV) providing

they are all in the same units.

|

| |

What type

of errors occurred in load cell outputs?

|

Non-linearity, hysteresis

and creep errors are most commonly considered

errors in load cell application.

|

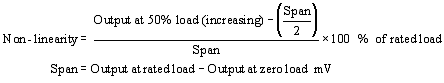

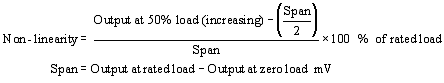

Non linearity

If measurements are being made in one direction

only the non-linearity describes how they

reliance upon a linear output, which is

normally assumed for scaling on amplifier

or meter, can lead to the linearity error

being applied to the measurement point over

the entire range of the load cell.

|

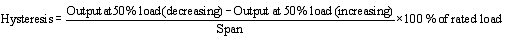

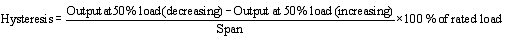

Hysteresis

Our hysteresis data is achieved by using

the mid load point as the reference point

to calculate hysteresis during an incremental

and decremental calibration of the load

cell.

|

Creep: Creep is the

change in load cell output that occurs with

time when a constant load is applied with

environmental and other variables remaining

constant. Creep is specified over a fixed

time period, often 20 minutes.

|

| |

How Environmental

factors affect the load cells?

|

Temperature

Generally temperature changes will result

in a change in a load cell's physical dimensions,

shift in the zero balance of the bridge

and a small change in the Young's modulus

or stiffness of the structure of the load

cell causing an output span change.

|

Pressure

For particular types of load cell, static

or dynamic ambient pressure changes can

cause error due to a net resultant force

exerted on a sensitive form area. |

| |

Load cell

calibration

|

Load cell calibrated by using

one of the three methods.

• Dead weight

• Lever

• Hydraulic |

| |

Application

fields

|

• Automatic dispensers

• Tablet testing

• Pipette control

• Dynamic or fast weighing

• Crystal growing machines

• Ashing and residue analysis

• Tensionmetry

• Thermogravimetry |

| |