|

ARTICLES |

| |

| |

Encoder

|

|

An

encoder is device used to change a signal

or data into code. An encoder is circuit

that converts binary information from 2n

input lines to n output lines. It is used

for compressing information for transmission

or storage, encrypting or adding redundancies

to the input code, or translating from one

code to another.

Usually only one of the

input is 1 and all others are zero. The

output is binary codeword corresponding

to the input that is 1. Since only one input

is 1 at a time only n rows are needed in

the truth table rather than 2n row. The

remaining rows contribute don’t care

condition. If more than one input is 1 at

a time, encoder will not produce valid output.

Only priority encoder allows more than one

of their inputs to be active. Each input

has a priority assigned to it. The code

word produced as the output corresponds

to that of the highest priority input among

all the inputs that are active.

|

| |

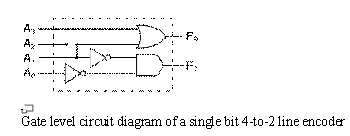

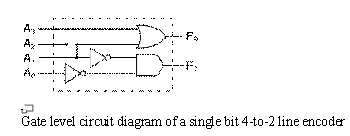

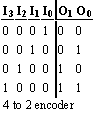

Single

bit 4 to 2 Encoder

|

An encoder has

2n input lines and n output lines. The output

lines generate a binary code corresponding

to the input value. For example a single

bit 4 to 2 encoder takes in 4

bits and outputs 2 bits. It is assumed that

there are only 4 types of input signals

these are: 0001, 0010, 0100, and 1000.

|

| |

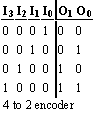

Priority

Encoder

|

A priority encoder

is a combinational circuit with m= 2n and

n outputs. Each of the m inputs is assigned

a priority. The most significant bit of

the input has the highest priority while

the least significant bit has the lowest

priority. The n bits of the output are the

binary index of the non-zero input bit with

highest priority, all input bits with lower

priority will be ignored. For example, when

n=2 and m=4, the behavior of the priority

encoder can be described as the following

truth table:

Priority encoders are typically used when

multiple components (e.g., processor, memory,

I/O devices, etc.) are to share a common

resource (e.g., a bus). Each component is

assigned a certain priority according to

its nature, so that whenever there is a

conflict, the component with the highest

priority will be granted the usage of the

resource.

A binary decoder can be used to convert

the n-bit output of a priority encoder to

a set of m=2n bits each for one of the m.

|

| |

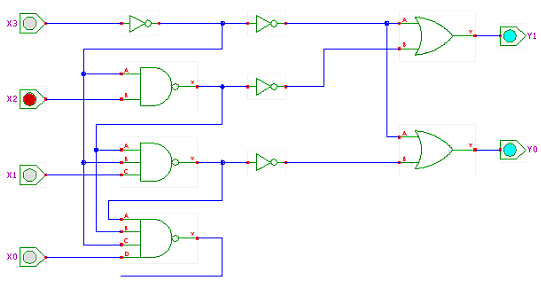

Circuit

Description

|

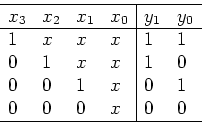

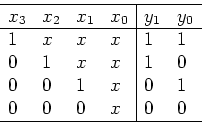

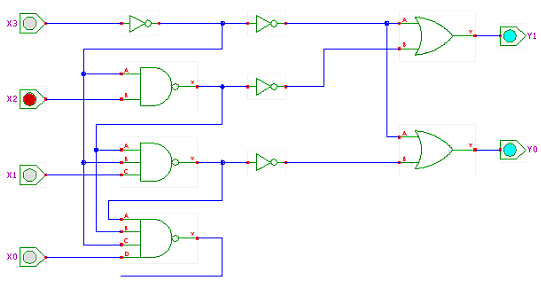

A 4-bit priority

encoder converts the 4-bit input into a

binary representation. If the input n is

active, all lower inputs (n-1 ... 0) are

ignored:

x3 x2 x1 x0 y1 y0

------------------

1 X X X 1 1

0 1 X X 1 0

0 0 1 X 0 1

0 0 0 X 0 0

The circuit operation is simple. Each output

is driven by an OR-gate which is connected

to the NAND-INV outputs of the corresponding

input lines. The NAND gate of each stage

receives its input bit, as well as the NAND

gate outputs of all higher priority stages.

This structure implies that an active input

on stage n effectively disables all lower

stages n-1... 0.

A common use of priority encoders is for

interrupt controllers, to select the most

critical out of multiple interrupt requests.

Due to electrical reasons (open collector

outputs), priority encoders with active-low

inputs are also often used in practice.

Application:

• Driving LED displays

• Driving incandescent displays

• Driving fluorescent displays

• Driving LCD displays

• Driving gas discharge displays

|

| |

Connecting

Priority Encoders

|

Priority encoders

can be easily connected in arrays to make

larger encoders, such as a 16 to 4 encoder

made from six 4 to 2 priority encoders (four

encoders having the signal source connected

to their inputs, and two encoders that take

the output of the first four as input).

|

| |

Rotary

encoder

|

A rotary encoder,

also called a shaft encoder, is an electro-mechanical

device used to convert the angular position

of a shaft or axle to an analog or digital

code, making it an angle transducer. These

devices are used in industrial controls,

robotics, in top-of-the-line photographic

lenses, in computer input devices (such

as optomechanical mouse and trackballs),

and in rotating radar platforms. A rotary

encoder converts rotary position to an analog

(e.g., analog quadrature) or digital (e.g.,

digital quadrature, 32-bit parallel, or

USB) electronic signal. Rotary Encoders

are ideal solutions for applications requiring

measurement of speed, length, travel, direction

of rotation etc. They are robustly constructed

to withstand the conditions encountered

in industry such as Printing, Packaging,

Metal Processing, Textile and Machine Tool.

There are two main types: absolute and incremental

(relative).

Absolute rotary encoder

Construction

The absolute digital type produces a unique

digital code for each distinct angle of

the shaft. They come in two basic types:

optical and mechanical.

Mechanical Absolute Encoders

A metal disc containing a set of concentric

rings of openings is affixed to an insulating

disc, which is rigidly fixed to the shaft.

A row of sliding contacts is fixed to a

stationary object so that each contact wipes

against the metal disc at a different distance

from the shaft. As the disc rotates with

the shaft, some of the contacts touch metal,

while others fall in the gaps where the

metal has been cut out. The metal sheet

is connected to a source of electric current,

and each contact is connected to a separate

electrical sensor. The metal pattern is

designed so that each possible position

of the axle creates a unique binary code

in which some of the contacts are connected

to the current source (i.e. switched on)

and others are not (i.e. switched off).

Optical Absolute Encoders

The optical encoder's disc is made of glass

with transparent and opaque areas. A light

source and photo detector array reads the

optical pattern that results from the disc's

position at any one time.

This code can be read by a controlling device,

such as a microprocessor, to determine the

angle of the shaft.

The absolute analog type produces a unique

dual analog code that can be translated

into an absolute angle of the shaft (by

using a special algorithm).

Incremental rotary encoder

An incremental rotary encoder, also known

as a quadrature encoder or a relative rotary

encoder, has two outputs called quadrature

outputs. They can be either mechanical or

optical. In the optical type there are two

gray coded tracks, while the mechanical

type has two contacts that are actuated

by cams on the rotating shaft. The mechanical

types require debouncing and are typically

used as digital potentiometers on equipment

including consumer devices. Most modern

home and car stereos use mechanical rotary

encoders for volume. Due to the fact the

mechanical switches require debouncing,

the mechanical type are limited in the rotational

speeds they can handle. The incremental

rotary encoder is the most widely used of

all rotary encoders due to its low cost.

Incremental encoders are used to track motion

and can be used to determine position and

velocity. This can be either linear or rotary

motion. Because the direction can be determined,

very accurate measurements can be made.

Rotary sensors with a single output are

not encoders and cannot sense direction,

but can sense RPM. They are thus called

tachometer sensors.

|

| |

Sine

wave encoder

A variation on the Incremental encoder is

the Sine wave Encoder. Instead of producing

two quadrature square waves, the outputs

are quadrature sine waves (a Sine and a

Cosine). By performing the arctangent function,

arbitrary levels of resolution can be achieved.

Linear encoder

A linear encoder is a sensor, paired with

a scale that encodes position. The sensor

reads the scale in order to convert the

encoded position into an analog or digital

signal, which can then be decoded into position

by a digital readout (DRO). Motion can be

determined by change in position over time.

Linear encoder technologies include capacitive,

inductive, eddy current, magnetic, and optical.

Optical technologies include shadow, self

imaging and interferometric. Linear encoders

are used in metrology instruments and high

precision machining tools ranging from digital

calipers to coordinate measuring machines.

A linear encoder similarly converts linear

position to an electronic signal.

|

Resolutions

|

Resolutions

is a measure of how many counts per unit

distance encoder generates. With rotary

encoder, resolution is expressed in either

in unit of angle(degrees- minutes- second,

decimal degrees, grad or radians) or number

of measuring steps per resolutions.

|

Accuracy

|

Accuracy is

measure of where the encoder says vs. where

it actually is. It is expressed in unit

of angle.

|

Encoder

technologies

|

Encoders may

be implemented using a variety of technologies:

• Conductive tracks: A series of copper

pads etched onto a PCB is used to encode

the information. Contact brushes sense the

conductive areas. This form of encoder is

now rarely seen.

• Optical: This uses a light shining

onto a photodiode through slits in a metal

or glass disc. Reflective versions also

exist. This is one of the most common technologies.

• Magnetic: Strips of magnetised material

are placed on the rotating disc and are

sensed by a Hall-effect sensor or magnetoresistive

sensor. Hall effect sensors are also used

to sense gear teeth directly, without the

need for a separate encoder disc.

|

| |

Interface

technology

|

Parallel

Interface:

In Parallel Interface all bits of a position

are transferred simultaneously using one

line for each bit. Data transmission is

done by two transistors in push pull circuit.

The bit parallel interface is a very fast

and for low resolutions cheap possibility

of data transmission. For high resolutions

or machines of bigger size installation

costs can rise rapidly so that other methods

of data transmission are more favorable.

SSI:

The position value is transmitted synchronously

to the clock signal of the control system

starting with the most significant bit (MSB).

When non-operational the clock as well as

the data line is high. As soon as the clock

signal of a clock sequence changes for the

first time from high (H) to low (L), the

bit-parallel data on the parallel-serial-converter

will be stored via an internal S Load-Signal

in the input latch of the shift register.

This ensures that the data cannot change

during the transmission of a position value.

With the following rising edge transition

of the clock signal the transmission begins

with the most significant bit (MSB). With

each following rising edge transition of

the clock signal, the next lower significant

bit is set on the output of the data line.

After the least significant bit was shifted

out, the last rising edge transition of

the clock signal switches the data line

to low (transmission end). |

| |

|

| |

|

|

|

|

|

|

|